The Decapod

In 1903 the Great Eastern Railway constructed a massive 0-10-0 tank engine which, at the time, was the largest locomotive constructed for a British railway company. Universally known as the ‘Decapod’, it has become one of the least-understood locomotives in British railway history, and many myths and misconceptions have grown up around it.

Background

The Great Eastern Railway was formed in 1862 by the amalgamation of several railway companies in East Anglia. In truth, its formation by Act of Parliament was the formalising of the many leasing and working arrangements by which the Eastern Counties Railway had gained control of the other railways in the region.

The ECR had been the first railway in the region, intended to link London and Norwich, by way of Colchester and Ipswich. Its first section had opened in 1839 between Mile End and Romford, being extended in either direction to its London terminus at Shoreditch, and to Brentwood. The Shoreditch terminus was the closest that the company was allowed to approach the hallowed precincts of the City of London at the time.

Although later re-named Bishopsgate, its position was inconvenient, but the company was initially optimistic that commercial development would spread northwards from the City boundary towards the station. This did not happen, however, with the result that the terminus did nothing to encourage traffic.

Shortly after the incorporation of the GER, encouraged by the opening of the North London Railway's terminal at Broad Street, the new company put forward a Bill to extend to a new City terminus alongside the North London's premises, to be called Liverpool Street. Included in the Bill were proposals for new suburban lines, primarily between Bethnal Green and Clapton, to join the Cambridge main line. This would shorten the existing route, and avoid the busy junctions that had grown up around Stratford.

Parliamentary approval was eventually given, but with the proviso that the GER had to offer cheap workmen's fares on its Walthamstow/Chingford and Enfield lines. This was intended to compensate the two thousand-odd families that would be displaced by the extension to Liverpool Street. They were expected to move to the areas served by these lines. However, the affected families merely moved to the already-overcrowded nearby slums of Hoxton and Spitalfields. Instead, the better off artisans and clerks moved into these areas, attracted by the cheap fares.

The new Liverpool Street terminus opened for suburban traffic in 1874, and to all traffic in the following year. Over the next fifteen years, the suburban traffic increased exponentially, especially on the Chingford and Enfield lines. By the late 1890s the suburban services were at crisis point. The trains ran as frequently as the signalling system allowed, and they were as long as could be accommodated in the platforms, but they were still hopelessly overcrowded. Worse, they hardly covered their costs, and the GER campaigned tirelessly to have the crippling cheap fares obligations removed, but to no avail.

In 1890 the first of the London electric 'tube' railways opened. This gave rise to a number of proposals for new underground electric lines, two of which were to cut across the GER's north-east London territory. The GER countered by taking out Parliamentary powers to electrify their own suburban lines although, in reality, the company was in no position financially to carry this through. In the meantime, James Holden, the Locomotive Superintendent, was instructed to show that a conventional steam locomotive was capable of equalling the performance claimed for electric traction, i.e. to accelerate a 300 ton train to 30 mph in 30 seconds.

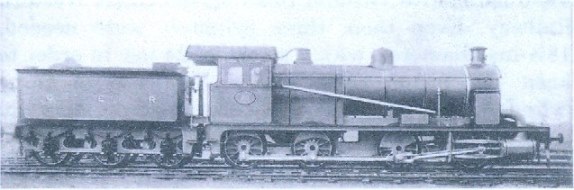

The Locomotive

Holden's initial thoughts were for a 0-8-0 tank engine, and he delegated the task to his brilliant ex-apprentice Frederick V. Russell, then head of the Locomotive Design section of the Drawing Office. Russell calculated that the engine would need to be larger, and the massive ten-coupled locomotive known as ‘The Decapod’ was born.

Although basically a conventional steam locomotive, it was packed with novel features that were new to British and World practice, only a few of which can be noted here. The critical dimensions that governed its performance were the boiler working pressure, size and number of cylinders, and the diameter of the driving wheels. The latter were finalised at 4-ft. 6-ins. diameter to give rapid acceleration and a moderate top speed. A high boiler pressure of 200 lbs. per square inch was chosen, in order to keep the cylinders of reasonable size. This pressure was only matched at the time by the first Dean/Churchward 2-cylinder 4-6-0 locomotive William Dean on the Great Western Railway. Even then, three cylinders were needed, 18½-ins. diameter, with a stroke of 24-ins. in order to keep the piston speed down. The use of three cylinders also produced a smoother turning effort to the wheels, and simplified the balancing of the engine.

The problem with the cylinders was that they needed to be horizontal, in order to avoid the tendency for the adhesive weight to vary with each piston stroke if inclined cylinders were used. There was no problem as regards the outside cylinders, but an ingenious solution was required to enable the inside cylinder to effectively drive through the leading axle. This Holden and Russell provided by using a 'Y'-shaped connecting rod that enclosed the leading axle, which had a small 'set' in it to clear the connecting rod. At this period,only two or three simple-expansion three-cylinder locomotives had been built, but the 'Decapod' was the first in which the cranks were set at 120 degrees to one another.

Apart from having the high working pressure of 200 lbs. psi., the boiler had to be of large size, in order to produce steam in sufficient quantities to power the engine. A grate area of 42 square feet was needed, dictating a firebox length of twelve feet, which was clearly out of the question. Russell therefore opted for the American 'Wooten' type wide firebox, 7-ft. wide and 6-ft. long. This type of firebox was being used for the first time in Britain by H.A. Ivatt on the Great Northern Railway on his 'Large Atlantic' 4-4-2 No. 251. The boiler barrel was nearly sixteen feet long, and 5-ft. 4¼-ins. in diameter, and was easily the largest locomotive boiler constructed in Britain at the time. As the firebox sat on top of the rear wheels of the engine, Russell used a divided Ashpan, a feature not seen again in Britain until O.V.S. Bullied's Merchant Navy 4-6-2 locomotives for the Southern Railway nearly forty years later.

The boiler had to be pitched nine feet above rail level, and thus the chimney and dome were unusually squat in design. The safety valves were an adaptation of the Ramsbottom type in order to fit within the loading gauge. Moreover, no less than six valves were used.

It was due to the large size of the boiler that ten wheels were required to carry the weight. These, in turn, needed to be coupled together or there would be insufficient adhesive weight to avoid wheelspin. To enable the engine to pass over curves the centre driving wheel was flangeless, whilst the trailing axle was given 1½ inches of side-play, controlled by nests of coil springs in the axlebox flanges, bearing on the hornguides. This necessitated additional articulated joints in the coupling rods. Sanding was by compressed air from the brake pumps - two of which were provided - the operation being controlled by a rotating sleeve around the regulator handle, forward or reverse sanding being selected automatically by a valve worked by the reversing gear.

It would seem that Holden and Russell contrived to conceal the total weight of the engine from the Civil Engineer. [Although this statement appeared in the original 2005 Information Leaflet, it has now been shown to be incorrect]. A provisional weight diagram produced in May 1902 showed the engine with side tanks holding 2350 gallons of water, and a bunker containing 3½ tons of coal, with an 'approximate weight loaded' of sixty tons. As built, the engine had well tanks holding only 1400 gallons and a 2-ton bunker, and tipped the scales at no less than eighty tons. This gave a load per foot run of wheelbase of 4.07 tons per foot, which is a high value even today. Given the meticulous calculations Russell made to arrive at the leading dimensions and details of the engine, it is inconceivable that he so badly under-estimated its final weight!

The Acceleration Trials

The locomotive was given the number 20, and made its first trial trip on 11th January 1903, from Stratford to Romford and return, following which it returned to the Works for adjustments. To test its acceleration, a stretch of some 450 yards of level track on the Up Through line at Chadwell Heath was adapted for the purpose. Electric contacts were arranged along the track, and the locomotive carried a wire brush that completed a circuit as it passed over each of the contacts. The electrical circuit operated a pen on a moving roll of paper on the recording apparatus, housed in a small hut beside the track.

The tests were carried out on Sundays, when the main line traffic could be diverted over the local (slow) lines. During these tests, the engine was serviced at Brentwood, and it is recorded that it achieved 55 mph when running light down Brentwood Bank.

For the tests themselves, the engine was coupled to a train of eighteen suburban four-wheeled carriages, loaded with pig iron so that locomotive and train together weighed some 335 tons. The target acceleration rate was 1.46 feet per second, per second. The initial tests in February yielded 1.20 ft/sec/sec, and subsequent runs raised this figure until the target rate was achieved on 26th April 1903, in less than ideal weather of rain and blustery winds.

After the Trials

The opportunity was taken to examine the acceleration of a number of other types of GER locomotive for comparison, although only some details of these tests have survived. The ‘Decapod’ meanwhile retired victorious to Stratford Works. It was the star attraction of visit by the Institute of Civil Engineers to the Works on 17th June 1903, a celebratory dinner being held in the evening.

It cannot be said that the ‘Decapod’ was the only factor that defeated the rival tube railway proposals. In the time that the engine was built and tested, the suburban crisis abated somewhat, due mainly to the introduction of electric tramways that siphoned off a lot of the inner suburban traffic, and the rival proposals eventually came to nothing.

The engine itself was totally unsuitable for work in its form as built. It was too heavy for most of the bridges, and its wheelbase too long for many of the curves and point-work, particularly at Liverpool Street. Moreover, its coal and water capacity meant that it would probably have run out before even reaching Chingford! The contemporary 0-6-0Ts had 1200 gallon tanks and 2½-ton bunkers and weighed 43 tons. The ‘Decapod’ weighed more than twice as much, carried only 200 gallons more water, and half a ton less coal.

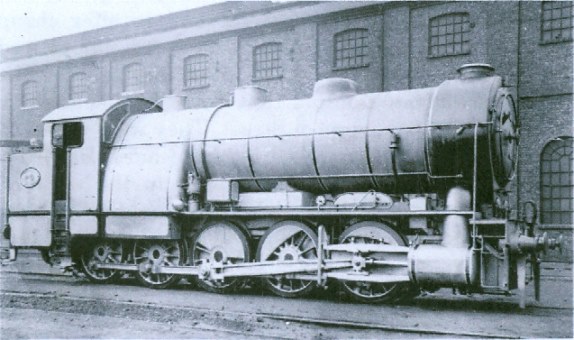

The engine languished on a siding at the Works until a decision was reached as to its fate. In May 1904 it was decided to 'rebuild' it as an 0-8-0 goods tender locomotive, in which form it eventually re-appeared in October 1906. The rebuilding was a book-keeping exercise, for very little of the original locomotive was re-used apart from two cylinders, four wheelsets (heavily modified), and the front buffer beam. It worked on the Cambridge line hauling coal trains until its non-standard boiler needed major repair, whereupon it was quietly scrapped, in December 1913.